- You have no items in your shopping cart

- Continue Shopping

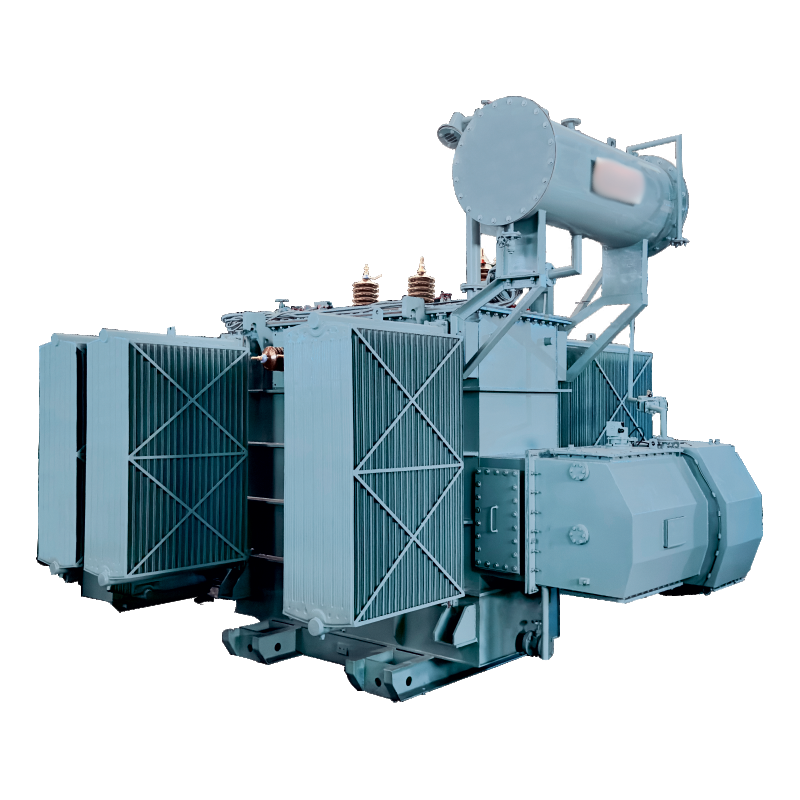

Induction Furnace has coil constructed from heavy copper tubing. It is designed and tuned to the inverter circuit which applies a medium frequency (generally 500 Hz or 1000 Hz) voltage to the Induction coil. The magnetic field produced by the induction coil induces eddy currents in the charge and heats it. Medium frequency is necessary to enhance the rate of heat generation.

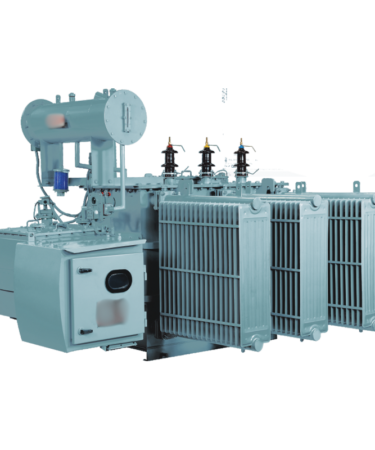

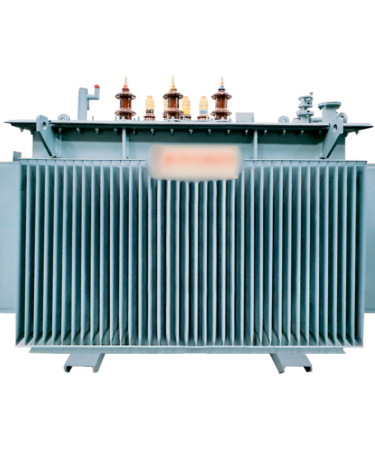

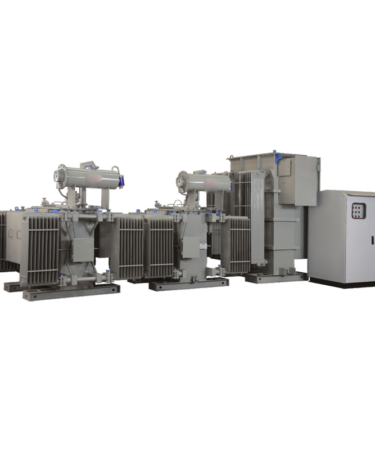

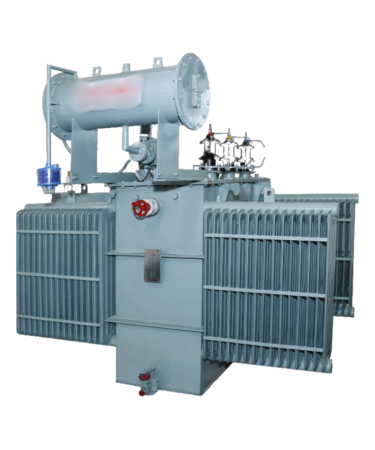

The inverter circuit requires for its operation a D.C. Voltage which is obtained by converting available three phase A.C. Voltage. Transformers which are used for transforming available three phase A.C. voltage to required voltage for converter circuit of the Induction Furnace are referred to as Induction Furnace Transformers. Thus they are essentially Rectifier/ Converter Duty Transformers.

These transformers must be designed to resist the high levels of electrical, thermal and mechanical stress to which they are subject during utilisation.

The furnace transformer thus has special features to handle such high currents as compared to conventional transformers. The electric arc furnace has 3 electrodes connected to the secondary terminals of the furnace transformers.

The secondary terminals of the transformers are subject to frequent short circuits during the melting process through the charge and arc. Hence the furnace transformer needs to be specially designed to withstand the frequent short circuits.

Customer reviews

Reviews

There are no reviews yet.

Write a customer review